As an expert in the field of glass manufacturing and usage, I have come across numerous questions about the different types of glass available. One of the most common inquiries is about the difference between tempered glass and regular glass. This article aims to provide you with valuable information on these two types of glass and help you make a well-informed decision for your specific needs.

What is the main difference between these two types of glass? Tempered glass is significantly stronger and more resistant to breakage compared to regular glass due to the unique manufacturing process it undergoes. On the other hand, regular glass, also known as annealed glass, is less durable and breaks into larger, sharper shards when damaged. By reading this comprehensive guide, you will gain a deeper understanding of the properties, uses, and benefits of both tempered and regular glass, allowing you to choose the best glass type for your project. So, let’s dive into the world of glass and learn more about these fascinating materials!

What is Regular Glass and its Common Uses?

Regular glass, also known as annealed glass, is the most basic type of glass available on the market. It is commonly used in a variety of applications, such as windows, picture frames, and glassware. Annealed glass is created by heating silica sand, soda ash, and limestone to extremely high temperatures, then cooling the molten glass slowly to room temperature. This gradual cooling process allows the glass to release internal stresses and achieve a uniform structure. However, it does not provide the same level of strength and safety as tempered glass.

When it comes to general applications and everyday use, regular glass is often the go-to choice for many people. The reason behind this preference is its affordability and ease of customization. Regular glass can be easily cut, shaped, and drilled, making it a versatile material for various projects. This type of glass is also widely used in artistic creations, such as stained glass windows and decorative glass panels, due to its ability to be crafted into intricate designs.

According to recent data, the global flat glass market size was valued at USD 115.8 billion in 2019 and is expected to grow at a compound annual growth rate (CAGR) of 4.3% from 2020 to 2027. This growth can be attributed to the increasing demand for regular glass in construction, automotive, and solar energy sectors. Despite its widespread usage, it is crucial to understand that regular glass has certain limitations, especially when it comes to strength and safety.

The Properties of Tempered Glass

Tempered glass is a type of safety glass that has undergone a specific manufacturing process to increase its strength and make it more resistant to breakage. This enhanced durability makes tempered glass an ideal choice for applications where safety and reliability are crucial, such as in automotive windows, shower doors, and glass railings. Its unique properties set it apart from regular glass, providing numerous advantages that we will explore in this section.

Difference Between Tempered Glass and Regular Glass: A Comprehensive Guide

Some key properties of tempered glass include:

- Increased strength: Tempered glass is approximately four to five times stronger than regular glass, thanks to the thermal treatment it undergoes during production.

- Improved safety: When broken, tempered glass shatters into small, relatively harmless granules instead of large, sharp shards, reducing the risk of injury.

- Resistance to heat: Due to the high temperatures used in the tempering process, tempered glass can withstand temperature fluctuations and higher levels of heat compared to regular glass.

- Scratch resistance: While not completely scratch-proof, tempered glass is more resistant to scratches and abrasions than regular glass.

These properties make tempered glass a popular choice for various applications where safety, durability, and resistance to damage are essential factors.

How Tempered Glass is Made

Tempered glass, also known as toughened glass, is a type of safety glass that has undergone a specific manufacturing process to increase its strength and resistance to breakage. The process involves heating the glass to extremely high temperatures and then cooling it rapidly, which results in a product that is much stronger and more durable than regular glass. This section will explore the key steps in the production of tempered glass.

The first step in making tempered glass is to cut the glass into the desired shape and size. This is done using specialized cutting tools and machines, ensuring precise measurements and clean edges. Once the glass has been cut, it is then thoroughly cleaned to remove any dirt or impurities that could affect the tempering process.

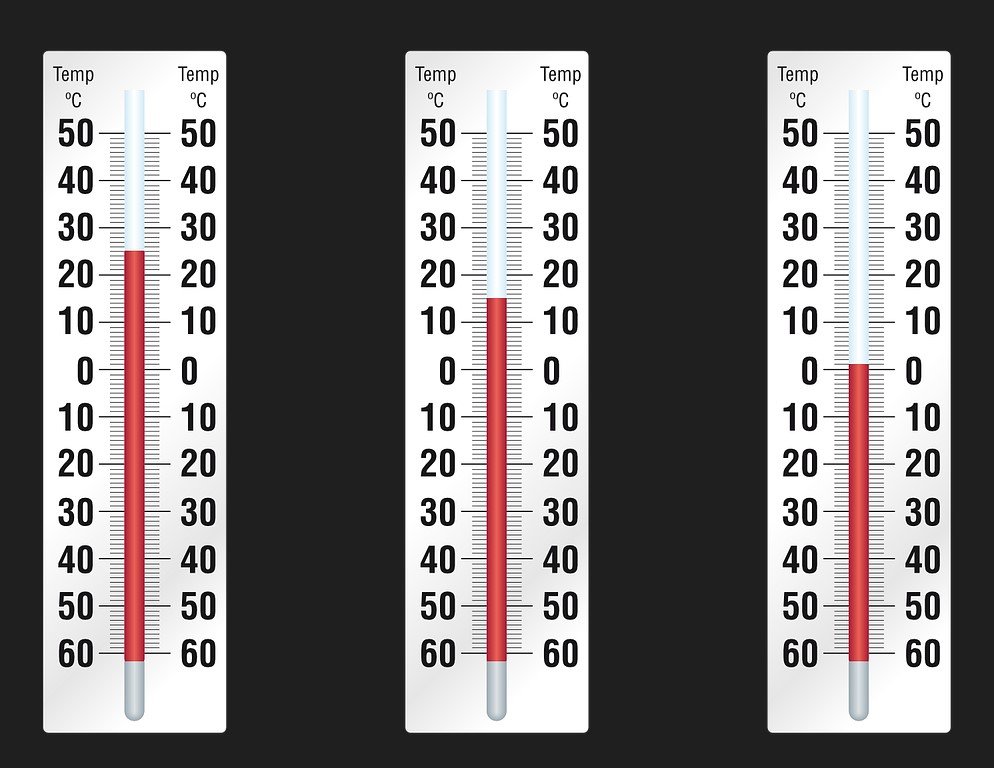

Next, the glass is heated in a furnace at temperatures ranging from 620°C to 720°C (1148°F to 1328°F). The exact temperature depends on the thickness and composition of the glass. This heating process allows the glass to become soft and pliable, making it easier to reshape if necessary.

After the glass reaches the desired temperature, it is rapidly cooled using high-pressure air nozzles. This process, known as quenching, causes the outer surfaces of the glass to contract and solidify while the interior remains hot and fluid. As the interior cools more slowly, it pulls the outer surfaces inward, creating tension that increases the glass’s overall strength and durability.

The final step in the tempering process is to inspect and test the finished product for quality and compliance with safety standards. This may involve visual inspections, impact tests, or other methods to ensure that the tempered glass meets the required specifications.

Overall, the production of tempered glass involves a series of precise steps, including cutting, cleaning, heating, and cooling. The result is a strong, durable, and safe glass product that is widely used in various applications, such as automotive windows, shower doors, and glass railings.

Advantages of Using Tempered Glass

Tempered glass offers several advantages over traditional, untreated glass. Its unique manufacturing process results in a stronger, more durable product that can withstand greater stress and impact without shattering. This section will discuss the main benefits of using tempered glass in various applications, including safety, durability, and design flexibility.

One of the primary advantages of tempered glass is its safety features. When subjected to sufficient force, tempered glass breaks into small, relatively harmless granules rather than the sharp shards produced by regular glass. This characteristic significantly reduces the risk of injury from broken glass, making it an ideal choice for applications such as storefronts, shower doors, and glass railings.

In addition to its enhanced safety properties, tempered glass also boasts increased strength and durability. The tempering process creates a surface compression that makes the glass up to five times stronger than untreated glass. This increased strength allows tempered glass to better resist impacts, pressure, and temperature fluctuations, making it suitable for a wide range of applications, including automotive windows and building facades.

Another advantage of tempered glass is its design flexibility. Because the glass can be cut and shaped before undergoing the tempering process, it can be customized to fit various designs and specifications. This versatility allows architects, designers, and homeowners to incorporate tempered glass into a wide variety of projects, from modern office spaces to stylish home interiors.

Finally, tempered glass offers improved thermal resistance compared to regular glass. Its ability to withstand high temperatures makes it an excellent choice for applications such as fireplace screens, oven doors, and other areas where heat resistance is crucial. This property not only enhances the glass’s safety but also contributes to its energy efficiency, as it can help to minimize heat transfer and maintain comfortable indoor temperatures.

In summary, tempered glass provides numerous advantages over traditional glass, including enhanced safety, increased strength and durability, design flexibility, and improved thermal resistance. These benefits make it an ideal choice for a wide range of applications, ensuring that both form and function are effectively addressed.

Disadvantages of Tempered Glass

While tempered glass offers many advantages, it also comes with some drawbacks that should be considered before choosing it for a particular application. These disadvantages include the inability to alter its shape after tempering, its higher cost, and potential issues with spontaneous breakage. This section will discuss these limitations in more detail.

The most significant disadvantage of tempered glass is that it cannot be cut or altered once it has undergone the tempering process. This means that any modifications, such as drilling holes or changing the shape, must be done before the glass is tempered. If changes are needed after the glass has been tempered, the entire piece must be discarded and replaced, which can be both time-consuming and costly.

Another drawback of tempered glass is its higher cost compared to regular glass. The tempering process requires specialized equipment and additional manufacturing steps, which increases the overall cost of production. Consequently, tempered glass is generally more expensive than untreated glass, making it less suitable for projects with tight budgets.

Lastly, tempered glass can sometimes experience spontaneous breakage due to the presence of nickel sulfide inclusions. These inclusions are microscopic imperfections in the glass that can expand and contract with temperature fluctuations. Over time, this expansion and contraction can cause stress within the glass, leading to sudden breakage without any apparent cause. While the risk of spontaneous breakage is relatively low, it is still a concern for certain applications, such as glass curtain walls or overhead glazing.

Choosing the Right Glass for Your Needs

Selecting the appropriate type of glass for a specific application is crucial to ensure safety, durability, and overall performance. With various options available, such as tempered glass, laminated glass, and annealed glass, it is essential to consider each material’s properties and weigh their advantages and disadvantages. This section will provide some guidance on how to choose the right glass for your needs.

Firstly, assess the primary requirements of the application. Consider factors such as safety, strength, thermal resistance, and aesthetics. For instance, if safety is a top priority, tempered glass may be the best choice due to its ability to break into small, harmless pieces. On the other hand, laminated glass provides better security against break-ins, as it remains intact even when broken, thanks to its interlayer.

Next, evaluate the environmental factors that may affect the glass’s performance. For example, if the glass will be exposed to harsh weather conditions or significant temperature fluctuations, it is essential to choose a material with high thermal resistance, such as tempered or insulated glass. Additionally, consider the location of the glass installation – will it be in a high-traffic area where impact resistance is crucial? If so, tempered glass may be the ideal choice.

Lastly, consider the project’s budget and the cost of the various glass options. While tempered glass offers many benefits, it is generally more expensive than annealed or laminated glass. Determine which features are most important for the specific application and weigh the cost against the benefits provided by each glass type.

Conclusion: To Wrap Up

Understanding the various types of glass, their manufacturing processes, and their unique properties is essential for making informed decisions when choosing the right glass for your needs. By considering factors such as safety, strength, thermal resistance, aesthetics, environmental factors, and cost, you can select a product that best suits your specific requirements, ensuring a satisfactory result and a pleasing experience.

So, as you explore the world of glass and its numerous applications, remember that the right choice can make all the difference in enhancing the beauty, functionality, and safety of your project. With careful consideration and a bit of research, you’ll be well on your way to finding the perfect glass solution that puts a smile on your face.

Frequently Asked Questions

[faq-schema id=”870″]