As the global automotive industry pivots towards electric vehicles (EVs), Japanese automotive parts makers are racing to adapt. The shift from internal combustion engines to electric powertrains presents both challenges and opportunities for these companies. With government mandates pushing for carbon neutrality by 2050 and the discontinuation of gasoline-powered cars by 2035, the pressure is on for Japan’s automotive parts industry to innovate and stay relevant in this rapidly evolving market.

Adapting to New Technologies

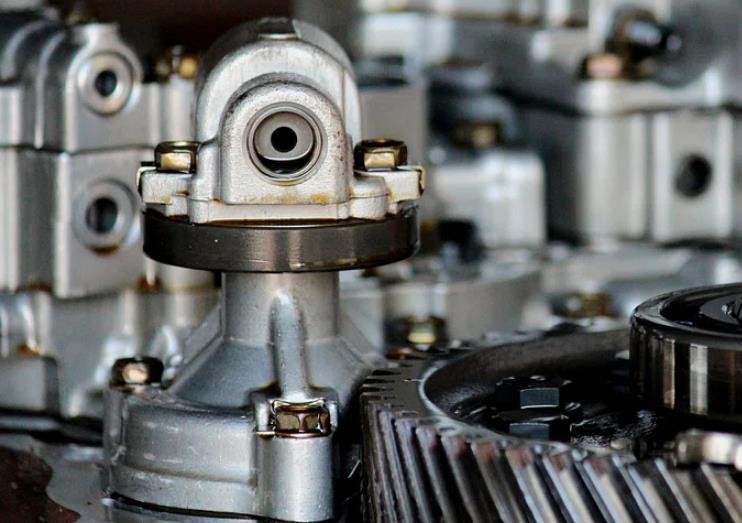

Japanese automotive parts manufacturers are investing heavily in research and development to keep pace with the EV revolution. Companies like KYB Corporation, known for its hydraulic shock absorbers, are now focusing on developing components for electric vehicles. This transition requires significant changes in their production processes and technological capabilities. The shift to EVs means that traditional parts, such as exhaust systems and fuel injectors, are becoming obsolete, necessitating a complete overhaul of product lines.

The challenge is not just technological but also economic. Many of these companies rely on long-standing relationships with automakers, and the shift to EVs disrupts these established supply chains. To mitigate this, parts makers are forming new partnerships and exploring collaborations with tech companies to integrate advanced electronics and software into their products. This collaborative approach is essential for staying competitive in the new automotive landscape.

Moreover, the transition to EVs is driving a need for new skills and expertise within the workforce. Companies are investing in training programs to equip their employees with the knowledge required to work with new technologies. This focus on education and skill development is crucial for ensuring a smooth transition and maintaining high standards of quality and innovation.

Economic and Environmental Impacts

The shift to electric vehicles has significant economic implications for Japan’s automotive parts industry. With over 20,000 parts manufacturers in the country, many of which are small businesses, the transition poses a risk to their survival. The reduction in the number of parts required for EVs compared to traditional vehicles means that some companies may struggle to find a place in the new market. However, this also presents an opportunity for those who can adapt quickly and innovate.

Environmental considerations are also at the forefront of this transition. The Japanese government has set ambitious targets for reducing carbon emissions, and the automotive industry plays a crucial role in achieving these goals. By developing components for EVs, parts makers are contributing to a more sustainable future. This shift not only helps in reducing greenhouse gas emissions but also aligns with global trends towards greener transportation solutions.

In addition to reducing emissions, the move towards EVs also involves addressing the environmental impact of manufacturing processes. Companies are adopting more sustainable practices, such as using recycled materials and reducing energy consumption in their factories. These efforts are part of a broader commitment to environmental stewardship and corporate responsibility.

Future Prospects and Challenges

Looking ahead, the future of Japan’s automotive parts industry is both promising and uncertain. The rapid pace of technological change means that companies must continuously innovate to stay relevant. This requires ongoing investment in research and development, as well as a willingness to embrace new business models and partnerships. The ability to adapt quickly to changing market demands will be a key determinant of success.

One of the major challenges facing the industry is the development of a robust supply chain for EV components. This includes securing access to critical materials, such as lithium for batteries, and establishing reliable logistics networks. The complexity of these supply chains requires careful planning and coordination, as well as collaboration with international partners.

Despite these challenges, there are also significant opportunities for growth. The global demand for electric vehicles is expected to rise sharply in the coming years, creating a substantial market for innovative components. Japanese parts makers, with their reputation for quality and reliability, are well-positioned to capitalize on this trend. By leveraging their expertise and embracing new technologies, they can play a leading role in the global transition to electric mobility.