As an expert in indoor air quality, I have seen firsthand the impact that humidity can have on our daily lives. One critical aspect that is often overlooked is non-condensing humidity. This factor plays a significant role in creating a comfortable and healthy living environment, and understanding it is essential for various industries.

So, what is non-condensing humidity? Non-condensing humidity refers to the amount of water vapor present in the air that is not in the process of condensation. It is essential to monitor and control non-condensing humidity levels to prevent issues such as mold growth, product degradation, and uncomfortable living conditions. By following the guidelines in this article, you will learn how to effectively manage non-condensing humidity in your home or workplace. Keep reading to discover the best practices for maintaining optimal humidity levels.

What is Non-Condensing Humidity and How Does It Differ from Condensing Humidity?

Non-condensing humidity refers to the amount of water vapor present in the air that is not in the process of condensation. This type of humidity is an essential factor to consider when evaluating indoor air quality and comfort levels. In contrast, condensing humidity occurs when the air temperature drops below its dew point, causing the water vapor in the air to condense into liquid droplets. This typically happens on cold surfaces like windows, walls, and pipes, leading to the formation of condensation or “sweat.”

Understanding the difference between non-condensing and condensing humidity is vital for maintaining a healthy and comfortable environment. Non-condensing humidity can have a significant impact on our daily lives, affecting our comfort, health, and the longevity of our belongings. For instance, high levels of non-condensing humidity can lead to mold growth, allergen accumulation, and increased risk of respiratory issues. On the other hand, low non-condensing humidity levels can cause dry skin, irritated eyes, and increased static electricity.

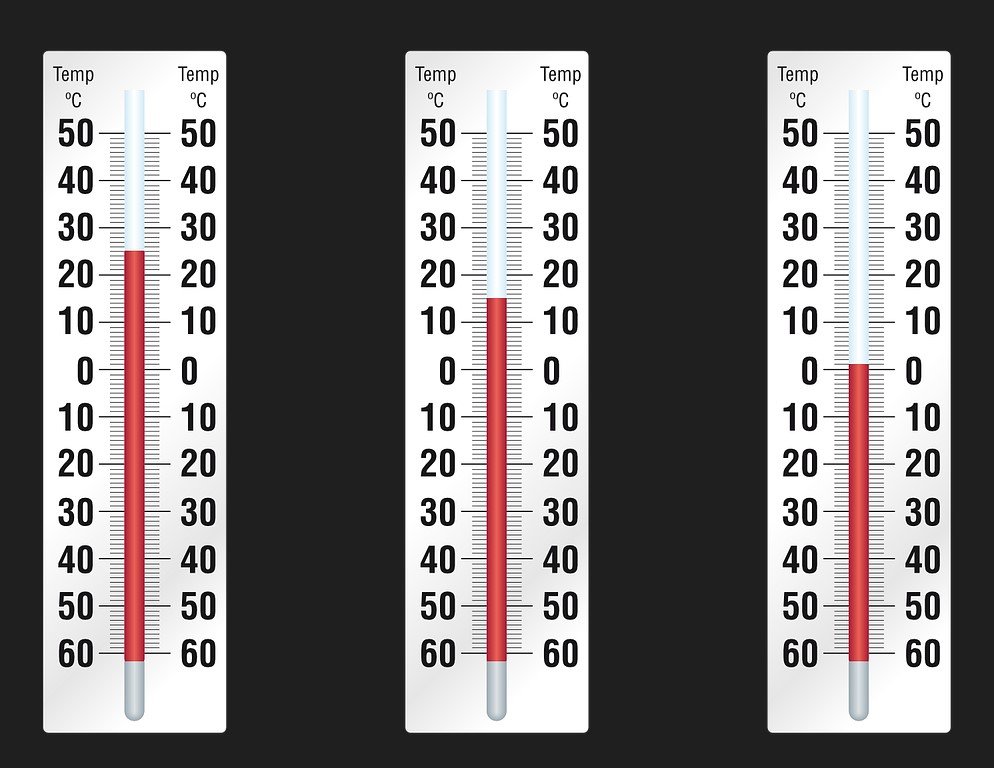

Recent studies have shown that maintaining optimal non-condensing humidity levels, typically between 40% and 60%, can significantly improve indoor air quality and reduce the risk of health problems. By understanding the distinction between non-condensing and condensing humidity, individuals and businesses can take the necessary steps to manage humidity levels effectively, ensuring a comfortable and healthy environment for all occupants.

5 Factors Affecting Non-Condensing Humidity Levels

Non-condensing humidity levels in a given environment can be influenced by several factors. These factors play a crucial role in determining the overall comfort and air quality of a space. Understanding these factors can help you manage non-condensing humidity more effectively and create a healthier living or working environment.

What is Non-Condensing Humidity: A Comprehensive Guide

- Temperature: The air’s ability to hold water vapor depends on its temperature. Warmer air can hold more moisture than cooler air, so higher temperatures often result in higher non-condensing humidity levels.

- Pressure: Atmospheric pressure also affects non-condensing humidity. Lower pressure allows the air to hold more water vapor, while higher pressure can reduce the air’s capacity to hold moisture.

- Moisture content: The amount of moisture present in the air, such as from evaporation or transpiration, directly impacts non-condensing humidity levels.

- Airflow and ventilation: Proper airflow and ventilation help regulate non-condensing humidity by allowing moist air to be replaced with drier air. Inadequate air circulation can lead to increased humidity levels and potential issues such as mold growth.

- Environmental factors: Certain environmental factors, like proximity to bodies of water or local weather patterns, can also influence non-condensing humidity levels in a specific area.

By considering these factors and their effects on non-condensing humidity, you can make informed decisions about how to manage humidity levels in your home or workplace.

Top 4 Benefits of Controlling Non-Condensing Humidity in Various Industries

Controlling non-condensing humidity is essential in various industries to maintain the quality and efficiency of processes and products. High levels of humidity can cause damage to equipment, materials, and even impact employee health. So, what are the top benefits of controlling non-condensing humidity in these industries?

- Improved Product Quality: By maintaining optimal humidity levels, industries can ensure that their products are free from defects caused by excess moisture. This results in higher quality products, ultimately leading to increased customer satisfaction and repeat business.

- Extended Equipment Life: Excess humidity can cause corrosion, mold, and other issues that can damage machinery and infrastructure. Controlling non-condensing humidity helps protect these investments, leading to a longer equipment life and reduced maintenance costs.

- Enhanced Employee Health and Safety: High humidity levels can create an uncomfortable working environment and even lead to health issues for employees. Controlling humidity reduces the risk of heat-related illnesses, respiratory problems, and other health concerns, promoting a safer and more comfortable work environment.

- Increased Energy Efficiency: Controlling non-condensing humidity can help industries optimize their heating, ventilation, and air conditioning (HVAC) systems. This results in lower energy consumption and reduced utility costs, contributing to a more sustainable and cost-effective operation.

By taking control of humidity levels, industries can experience numerous benefits that ultimately lead to better overall performance, improved product quality, and a healthier work environment.

How to Accurately Measure Non-Condensing Humidity

Measuring non-condensing humidity accurately is crucial for industries to maintain the efficiency and quality of their processes and products. Accurate measurements help businesses make informed decisions about their humidity control systems, ensuring optimal working conditions and preventing damage caused by excess moisture. In this section, we will discuss some essential tips and tools for accurately measuring non-condensing humidity.

To measure non-condensing humidity, industries can use various instruments, such as hygrometers, psychrometers, and dew point meters. These tools are designed to provide accurate readings of the humidity levels in the air. When selecting an instrument, it’s essential to choose one that is suitable for the specific industry and environment in which it will be used. Factors to consider include the temperature range, humidity range, and accuracy requirements.

In addition to using the right tools, it’s crucial to follow proper measurement procedures to ensure accurate results. Some best practices for measuring non-condensing humidity include:

- Calibrating the instruments regularly: This ensures that the devices provide accurate and reliable readings over time.

- Taking measurements at various locations and heights: This helps to get a comprehensive understanding of the humidity levels throughout the facility.

- Avoiding direct sunlight and heat sources: Exposure to direct sunlight or heat sources can cause inaccurate readings, so it’s essential to take measurements in shaded or temperature-controlled areas.

- Allowing sufficient time for the instrument to stabilize: Giving the device time to adjust to the environment will result in more accurate readings.

By following these best practices and using appropriate tools, industries can accurately measure non-condensing humidity, allowing them to make well-informed decisions about their humidity control systems and maintain optimal working conditions.

3 Effective Methods for Managing Non-Condensing Humidity

Managing non-condensing humidity is essential for various industries to maintain the efficiency and quality of their processes and products. Proper humidity management can help prevent damage caused by excess moisture, improve indoor air quality, and reduce energy costs. So, what are the top methods for managing non-condensing humidity in these industries?

- Use a Dehumidifier: Dehumidifiers work by removing excess moisture from the air, helping maintain optimal humidity levels and preventing condensation-related issues. They come in various types and sizes, so industries should select the most suitable option based on their specific needs and requirements.

- Increase Ventilation and Air Circulation: Ensuring sufficient airflow is essential for maintaining optimal humidity levels. Adequate ventilation helps remove excess moisture from the air, preventing condensation and mold growth. Industries should invest in high-quality ventilation systems, such as exhaust fans or air handling units, to ensure effective humidity control.

- Use Air Conditioning: Air conditioning systems play a significant role in managing non-condensing humidity. These systems not only cool the air but also help remove excess moisture, making them an essential component of humidity control. Industries should choose energy-efficient air conditioning systems with built-in humidity control features to maintain optimal humidity levels.

By implementing these three methods, industries can effectively manage non-condensing humidity, ensuring optimal working conditions, improved product quality, and reduced energy costs.

To Wrap Up

Controlling non-condensing humidity is crucial for many industries to ensure the efficiency and quality of their processes and products. By understanding the importance of managing humidity levels and implementing effective methods such as dehumidifiers, proper ventilation, and air conditioning, industries can prevent potential problems caused by excess moisture. This will ultimately lead to better overall performance, improved product quality, and a healthier work environment.

Frequently Asked Questions

[faq-schema id=”966″]